Russel Brothers Limited OWEN SOUND, ONTARIO Steelcraft Boat Builders

| Cancel / Muskoka Evergreen

Canadian List of Shipping 1956: Cancel [C.194451] registered at Port Arthur; built at Owen Sound in 1952. 20’ 8 x 8’ 1 x 4’ 6; 5 g.t.; 4 n.t.; 100 hp. Owned by Marathon Corporation of Canada Ltd., Toronto. Canadian List of Shipping 1970: Steel tug Cancel [C.194451] registered at Port Arthur; built at Owen Sound in 1952. 21’; 5 g.t. Transport Canada List 2002: Built by Russel-Hipwell Engine Co., Owen Sound, Ont. Transport Canada List 2002: Renamed b] Muskoka Evergreen in 2002. Owned by Muskoka Evergreen Tree Service Ltd., P.O. Box 152 Windermere, Ontario. Registered at Thunder Bay, Ontario 1970/12/04. Details for registered vessel MUSKOKA EVERGREEN (O.N. 194451) Date of closing: 2008-05-27. |

Gord Campbell comments (Jan. 17, 2018): "On my way up the ladder of jobs, I drove this boat as the raftsman. It was either that or pond leader. Cancel was way underpowered for its size. When Cancel was down for repairs, I also operated the Obabika which had a 750 Cat. three times the size of this.

I was the Raftsman. Two maybe three times a shift, I'd leave the long poles, walk the booms past the flow boxes, hop on Cancel, hook onto the pond boom drive a long way into the wood floating on the water eyeballing the amount of wood needed so that the Orville tug could continue to push the wood into the jackladder pond where the pond crew using short and long poles straighten out the wood onto the jack ladder.

The other important job position was Pond Leader who was crew leader for the Jackladder crew using short and long poles, lining up the wood in the inner bridge pond so the jack ladder moves the wood up to the saws, then to the bark drums, sorting tables, then to the piles or straight to the mill chipper. The skill and commitment of these crews determined the amount of wood dewatered per shift which was usually between 700 to 1000 cords per.

Orville and Cancel were the boats. After thirty years of heavy use, they broke down sometimes. Obabika came into replace Cancel or Orville - which was quite a learning curve of adapting operation. With 750 horses it was very easy to send the wood into the jack ladder pond.

When both Orville and Cancel needed repair, the company brought down the river sweepers to get the wood moving. It was the opposite operating technique to Obabika. With the Obabika you positioned the boat in relation to the flow boxes pushing the wood along the booms. Like I said Obabika was big and bad, I loved it.

With the sweepers we had to use both. I worked with the then boat driver. As strong as the other boats were, a good size log could stall the sweeper in the water. We had to work in pairs, keep the wood looser, which mean we had to scoop the main rafts more often. We didn't want the wood double level. We used the wakes of the sweepers to move the wood into the stream currents from the flow boxes."

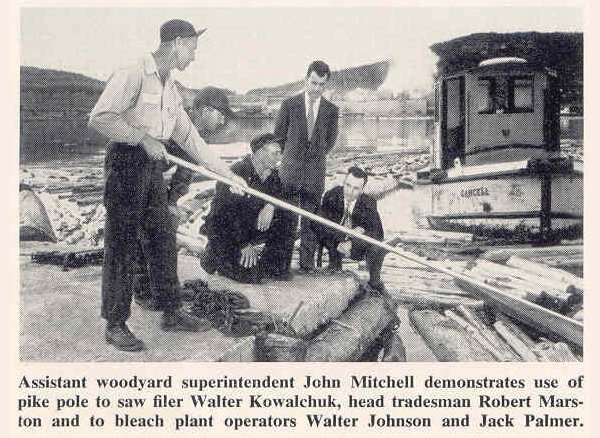

From Maralog Sept-Oct 1955 page 8, Marathon District Museum.

|

For more on the Marathon logging operations see Marathon ON Logging using Russel Tugs

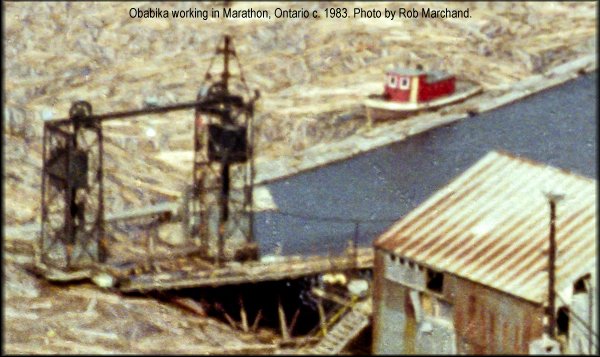

Rob Marchand comments: Here is a shot that captures one of the situations where Orville was out of action. Late 1983 or 1984, near the end of summer, but before Labour Day as #4 button shack had been replaced. Cancel and Obabika are tied up (it was lunchtime). This is in Marathon, overlooking Jellicoe Cove and Skin Island. Taken from the top of #4 stacker.

Gord Campbell comments: Looks more like 1984. Or maybe first week of October 1983. It can't be lunch because if you look at the pond, and the sorting table, the guys and girls would leave their poles and picaroons by their work stations. Also the Hog is empty and the work trucks are parked. That does look like Obabika. The orange dozer boat is Cancel. See the Boom pattern its catching a south wind. Number 4 button Shack is still there. In fact the picture taker is on a full number four softwood pile.

There is a Saturday crew. Probably putting up a stacker section. They did that on Saturdays at this time of year. This has to be the end of the season because the outer booms have been pulled between Skin Island and Cummings Beach off to the far right.

That isn't much wood. Maybe two three days tops.

Rob Marchand comments: I found the Orville in this photo (middle, taken the same day), up on the shore near #2. Bottom photo is a crop from the middle photo.

|

Aug. 16th, 2018, Gord Campbell continues:

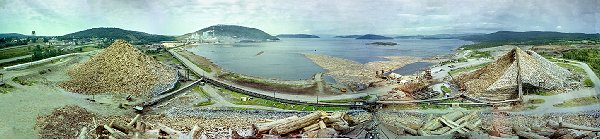

Cancel was used as a spare dozer. Its official title was Utility Boat which enabled the Woodyard Handyman to work. The Woodyard "Pond" was a large area of water occupying almost about 4/5 of Jellicoe Cove. The balance 1/5th was allocated to the main mill dock and shipping.

Wood would come by water pulled by a contract tug after the Peninsula tug was sold. Martin E. Johnson, and Polygon would often assist on the tow. They pushed the wood into the "Woodyard Pond". Inside that pond were booms dividing the pond into sections. They were pinned by mooring pilings. So the first job of Cancel was maintaining the chains, laying booms, and letting the handyman place, fix, hookup, repair booms, chains, pilings, and comb the beaches. Sometimes, the Handyman had to bring extra help if they landed at Skin Island to clean or "comb" the ice age smoothed red granite beaches.

That is why it was larger than Orville. When not used by the Handyman during operations, it was turned over to the Raftsman (me). The Raftsman used the vessel with the jack ladder raft boom attached. When the amount of floating logs depleted and the flow of wood slowed, the Raftsman would walk the booms out to Cancel, usually it was tied up to or right behind the Flow Boxes.

Then I would detach Cancel, work along the outside of the boom to the apex of the main central boom, then go scoop out wood floating free in the water into another tighter raft then tow it and tie back up to the flow boxes. If I did it right there was enough would to supply the jack ladder for another two hours.

Cancel working in Marathon, Ontario c. 1983. Photo by Rob Marchand.

Flow boxes were electric propellers driving a flow of water along the booms to the long pole men standing on the long pole bridge. There were two boxes. One each depending on which side was up-wind. To move the wood up to the Jack Ladder you employed the Rafting tug, Flow boxes, Ambient wind, Wave, and the Dozer Boat. The polemen on the Jack Ladder pulled, lined up and coaxed a smooth flow of wood up the Ladder.

The reasons I had to explain the functions of the Woodyard Dewatering Operation, is to explain the unique design of Cancel.

In its final role, back up Dozer boat. Orville took a beating. From 8:00 am Monday to Saturday 8:00am Orville would only stop long enough to drink some oil, fill the rad, and or change crew. Sometimes, Orville needed a major overhaul.

Enter Cancel. You know the word Utility implies a Jack of All trades and the over used phrase Master at none. Cancel was a poor replacement, but it was the only club in the golf bag.

Obabika working in Marathon, Ontario c. 1983. Photo by Rob Marchand.

Cancel was very under powered. It had the same engine as Orville in a hull four times the volume. It had a hard time busting up wood because when you tightened the raft often the floating wood would knit over top of each other two or three layers. That wood would be broken up, and metered into the water flow so it would arrive at the reach of the long polemen in a rather orderly fashion, it made their work easier and stack the ladder full up to the saws.

The photo of Orville was taken 35 years ago, by me. At lunch time. The resting person in the white T-shirt was Vince Poirier, the longest serving Boat Operator of Orville. So skilled he could do his job and maybe move the boat into position and the wood would break off and flow to the Jack Ladder. Then not move the boat for an hour while the inside raft emptied.

In addition, when both Cancel and Orville went out of commission once, I operated big powerful Obabika. The skill of a dozer boat operator is to understand how to use the hull and the advantages around you to move the floating wood to the long pole men standing on their Bridge. I also used, when Obabika was not available, two river punts normally used on the River drive to doze wood to the bridge.

But Orville had sufficient power and manoeuvrability. It did the job. I've seen other BC designs of Dozer boat, but I don't know how they would handle in swell. In those machines they pushed wood, with Orville you used it as a guide. I hope that helps.

Marathon Woodyard and Pulp Mill c. 1983. Photo collage by Rob Marchand.

enlarge to 2048 pixels wide.

enlarge to 16384 pixels wide.

enlarge to 2048 pixels wide.

enlarge to 16384 pixels wide.

https://www.flickr.com/photos/cuss/46974893241/in/album-72157704868439235/

For more Russel exhibits visit Owen Sound Marine & Rail Museum 1165 1st Ave West, Owen Sound, ON N4K 4K8

(519) 371-3333  http://marinerail.com http://marinerail.com |